Technical Parameters | Technical Indicators | |

Water-Cement Ratio | 1:1-11:1 | |

Gelation Time (min) | ≤20 | |

7d Compressive Strength (MPa) | Water-Cement Ratio3:1 | ≥2.0 |

Water-Cement Ratio6:1 | ≥0.6 | |

Water-Cement Ratio9:1 | ≥0.2 | |

Single Slurry Setting Time (h) | ≥24 | |

Product Introduction

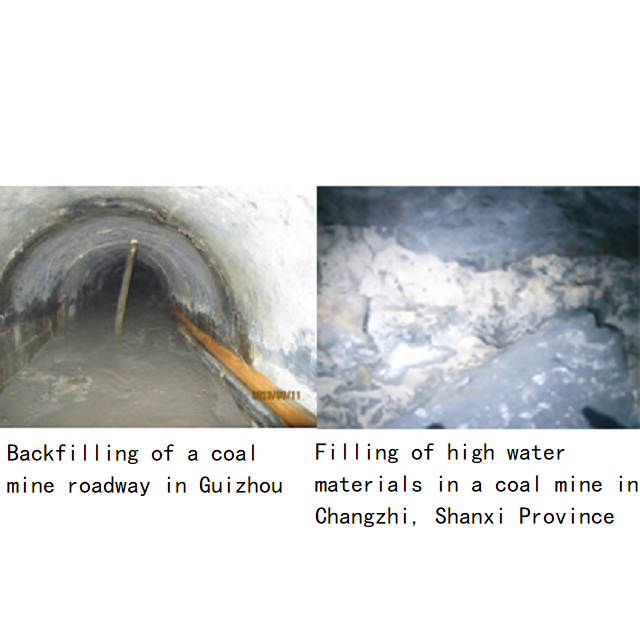

The high-water filling material is compounded from special cement clinker products, gypsum, lime, suspending agents, dispersants, and accelerators. It is a two-component (A and B) inorganic powder material. It can solidify rapidly under high water-cement ratio conditions, and the water content in the filled consolidated body is as high as over 90%. During construction, the slurries of the two powders, which are respectively mixed with water by professional equipment, are pumped to the filling area and mixed to solidify rapidly, playing a role in filling and reinforcement.

Performance Characteristics

High water content in the consolidated body, low filling construction cost, and good economic efficiency.

Short solidification time and no shrinkage.

Good fluidity of the slurry, easy to pump.

Simple process, good filling and reinforcement performance, and stable performance.

Scope of Application

Filling of underground cavities and behind support walls, and filling of goafs.

Building firewalls to isolate goaf gas and prevent coal spontaneous combustion.

Treatment of roof falls in mines, reinforcement of coal walls, and filling and reinforcement beside roadways.

Technical Parameters | Technical Indicators | |

Water-Cement Ratio | 1:1-11:1 | |

Gelation Time (min) | ≤20 | |

7d Compressive Strength (MPa) | Water-Cement Ratio3:1 | ≥2.0 |

Water-Cement Ratio6:1 | ≥0.6 | |

Water-Cement Ratio9:1 | ≥0.2 | |

Single Slurry Setting Time (h) | ≥24 | |