Application Examples

Case 1: Using the Seismic Monitoring Trajectory Instrument While Drilling to Interpret the Geological Section of a Cross - layer Borehole

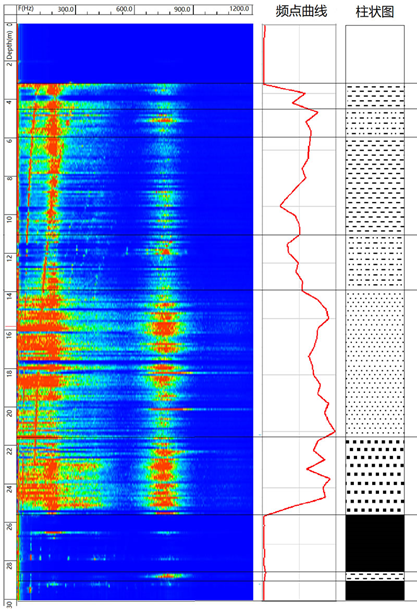

Seismic records of rock breaking are collected by a near - source three - component sensor. Through spectral analysis, the low - frequency spectrum represents the rotation speed, drill rod swing, etc., and the high - frequency spectrum corresponds to the lithology. By normalizing the high - frequency curve, information on the lithological layering during drilling can be obtained.

Frequency Point Curve:

Histogram:

Comparison Chart of Seismic Waveforms, Spectra and Geological Sections While Drilling in Cross-layer Boreholes of a Mine

Case 2: Using the Seismic Monitoring Trajectory Instrument While Drilling to Interpret the Coal Seam Structure and Drilling Depth of an In - layer Borehole

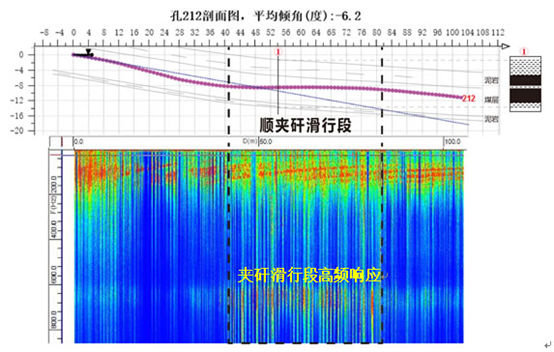

For in - layer borehole seismic monitoring while drilling, the response is generally low - frequency. If there is a gangue interlayer in the coal seam, a gliding phenomenon along the gangue interlayer will occur. The gliding distance along the gangue interlayer can be judged through the high - frequency band spectral response.

Profile View of Borehole 212, Average Inclination Angle: -6.2°

Sliding Section Along the Interburden Gangue:

mudstone

coal seam

Comparison Chart of the Trajectory of Gas Drainage Holes, Seismic Waveforms, Spectra and Coal Seam Sections in a Mine

Case 3: Using the Seismic Monitoring Trajectory Instrument While Drilling for Borehole Trajectory Measurement

The device uses high - precision sensors to measure the azimuth and inclination angles of the borehole. By combining with depth measurement, it can accurately depict the borehole trajectory and output planar graphs, sectional graphs, 3D graphs, data tables, CAD drawings, and other comparative analysis results.

planar graphs, sectional graphs, 3D graphs, data tables of the Borehole Trajectory Instrument in a Mine