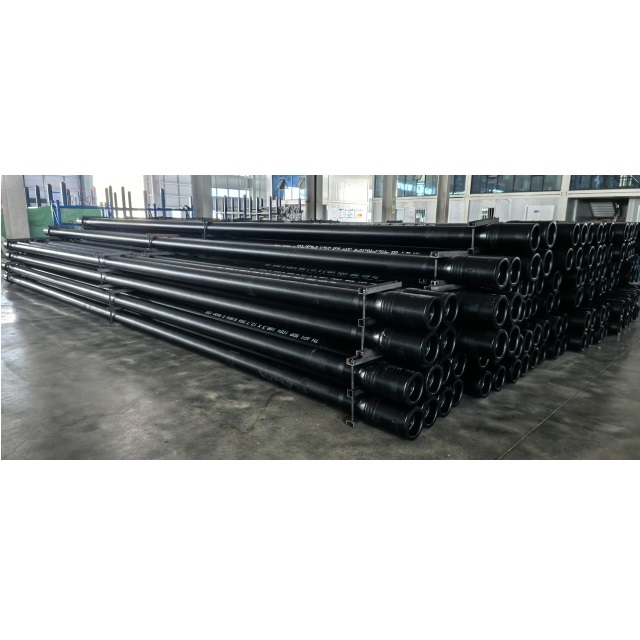

I. Conventional Drilling Pipes

1. Excellent steel purity, metallurgical quality, uniform structure, impact toughness, and fatigue resistance.

2. Adopting optimized Miu and Miu - R designs, combined with a special and stable upsetting process, to improve the fatigue resistance of the upset end of the drill pipe.

3. Based on the ERP system, the entire process from order to delivery realizes information - based management of the manufacturing process, inspection and test acceptance, and product traceability.

4. 100% FLUT (longitudinal, transverse, ultrasonic thickness measurement) for the pipe body + 100% MPI (or UT) for the pipe ends, 100% UT + 100% MPI for the drill pipe joints, and 100% UT + 100% MPI for the welds.

5. Integration: including drill pipe joint manufacturing, drill pipe upsetting, heat treatment, drill pipe welding, hardbanding wire deposition, and internal coating spraying.

II.Special Threads for Drilling Pipes

1. Improve the torque - resistant strength and makeup torque of the drill pipe joints, which is more suitable for extended - reach horizontal wells and ultra - deep wells.

2. Increase the inner diameter of the drill pipe joints to improve drilling hydraulic efficiency and drilling efficiency, especially suitable for extended - reach horizontal wells and ultra - deep wells.

3. Reduce the outer diameter of the drill pipe joints, which is more suitable for small - hole - diameter drilling, well workover, and improving fishing capabilities.

4. Improve the stress distribution, reduce the stress concentration factor, and improve the fatigue resistance of the drill pipe joints.

III. XT Series Joints

1. Compared with API joints, XT joints have the following characteristics: an improved double - shoulder structure, an improved thread root arc design, and optimized pitch and taper.

2. Ultra - high torque - resistant capacity. Compared with API joints of the same specification, the torque - resistant capacity can be increased by more than 70%.

3. High fatigue resistance and more durability.

4. Under the premise of ensuring torque - resistant performance, the outer diameter of the joint can be further reduced, and the inner diameter of the joint can be further increased.

5. Reduce the erosion - corrosion of the inner wall of the joint and improve hydraulic efficiency.

IV. Internal - flush Drilling Pipes

1. Reducing pressure loss and increasing hydraulic efficiency are the keys to improving the drilling rate. The pipe body of Taihe internal - flush drilling pipes adopts a special external upsetting technology to increase the inner diameter of the upset area, and the joints use Taihe special - thread series for connection to ensure a large water - way diameter. The inner diameter of the upset end, the inner diameter of the joint, and the inner diameter of the pipe body are almost the same.

2. The special external upsetting technology effectively reduces the stress concentration in the disappearing zone of the upset transition, reduces the possibility of fatigue failure, and increases the fatigue performance of the drill pipe.

3. The inner diameter of the joint is close to that of the pipe body.

4. The pressure loss is reduced by 20% - 50%, improving hydraulic efficiency and drilling speed.

5. The internal - flush structure is suitable for continuous coring and wire - line coring.

V. Heavyweight Drilling Pipes

1. Both integral heavyweight drill pipes and welded heavyweight drill pipes are manufactured by quenching and tempering (quenching + tempering) heat treatment process to ensure that the pipe body of the heavyweight drill pipe has better impact toughness.

2. Based on the ERP system, the entire process from order to delivery realizes information - based management of the manufacturing process, inspection and test acceptance, and product traceability.

3. 100% UT (longitudinal, transverse) for the pipe body, 100% UT + 100% MPI for the heavyweight drill pipe joints and welds.

4. Options to improve the performance of heavyweight drill pipes: increasing the tong length of the heavyweight drill pipe joints, making and breaking the threads, cold rolling of the threads, spiral grooves in the middle of the upset section, internal coating, and hardbanding.