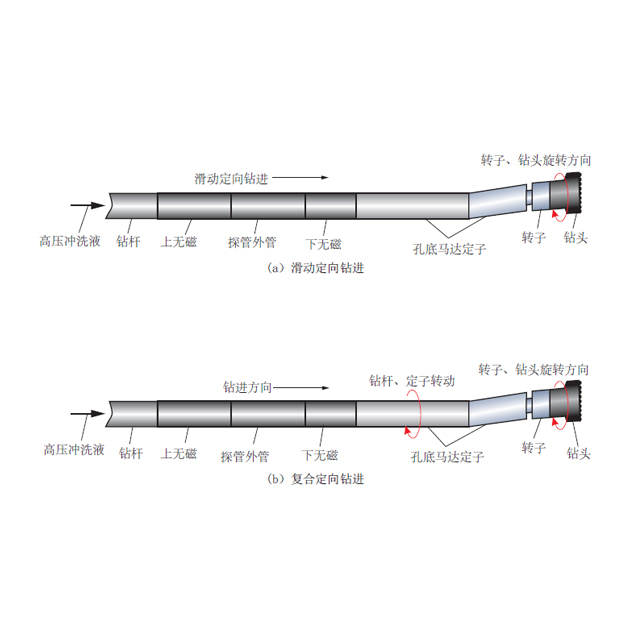

In the process of sliding drilling, the high-pressure mud drives the screw drilling tool, drill bit and rotor to rotate, the power head of the drilling rig and the drill only apply the drilling pressure to the hole without rotation, and the rest of the drilling tool slides in the axial direction; now, the tool face of screw motor can maintain “angle building by sliding” along a stable direction. Sliding drilling has weak slagging capacity, high drilling resistance and high load on drilling equipment.

In the process of combined drilling, the high-pressure mud drives the screw motor to drive the drill bit, while the power head of the drilling rig rotates the drilling tool and applies drilling pressure to the hole, so as to combine the two drilling modes of “angle building by sliding” and “angle stabilizing by rotation”. In the case of very hard stratum, “diamond bit driven by turbine drilling tool” or “screw drilling tool + hydraulic hammer” can be used to increase the impact load. Compared with sliding drilling, the combined drilling has stronger drilling capacity, larger hole diameter, higher utilization rate and stronger ability to deal with accidents in the hole. The power head of the drilling rig rotates the drilling tools to realize directional angle building by adjusting the screw motor for “angle stabilizing by rotation” and reduce the resistance, and meanwhile to achieve relatively high hole-forming rate in the long-distance directional drilling by virtue of improved rock breaking efficiency and slagging capacity.