Application Scenarios

(1)Stage Hydraulic Fracturing Gas Drainage Technology in Soft and Broken Coal Seams

The staged hydraulic fracturing technology for comb-shaped boreholes in coal seam roof and floor involves constructing main holes in the roof and floor strata of the coal seam. Along the main hole, branch holes are drilled at certain intervals towards the coal seam direction, and after entering the coal seam, they are appropriately extended. After the entire borehole construction is completed, a staged fracturing method is adopted to sequentially fracture and transform each branch borehole from the inside out, forming a fracture network channel to enable rapid migration and production of coal seam gas.

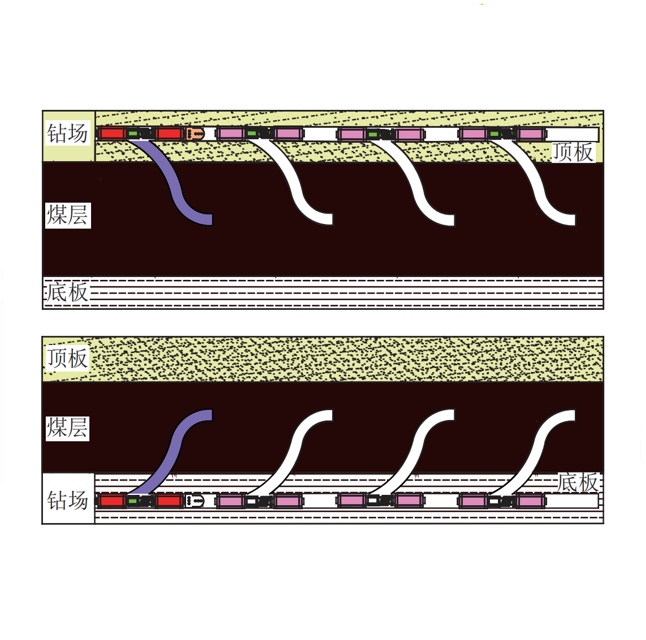

Schematic Diagram of Stage Fracturing of Comb-shaped Boreholes in Coal Seam Roof and Floor

The staged hydraulic fracturing permeability-enhancing technology for directional long boreholes in coal seam roof involves constructing directional long boreholes in the sandstone of the coal seam roof. Using a staged fracturing process, each section of the directional long borehole is fractured sequentially from the inside out, forming cracks in the roof strata that effectively communicate with the coal seam. With continuous fracturing, the coal seam itself initiates and generates cracks.

Schematic Diagram of Stage Fracturing of Directional Long Boreholes in Coal Seam Roof

(2)Stage Hydraulic Fracturing Gas Drainage Technology in Hard Coal Seams

The drag-type stage fracturing technology along the coal seam is adopted, fracturing section by section from the inside out to form a large-scale fracturing network around the borehole, increasing gas emission channels in hard coal seams, improving the effect and efficiency of gas pre-drainage, and reducing the workload of drainage boreholes.

Schematic Diagram of Open-Hole Staged Fracturing of Boreholes Along Hard Coal Seams

(3)Directional Long Borehole Stage Hydraulic Fracturing Tools

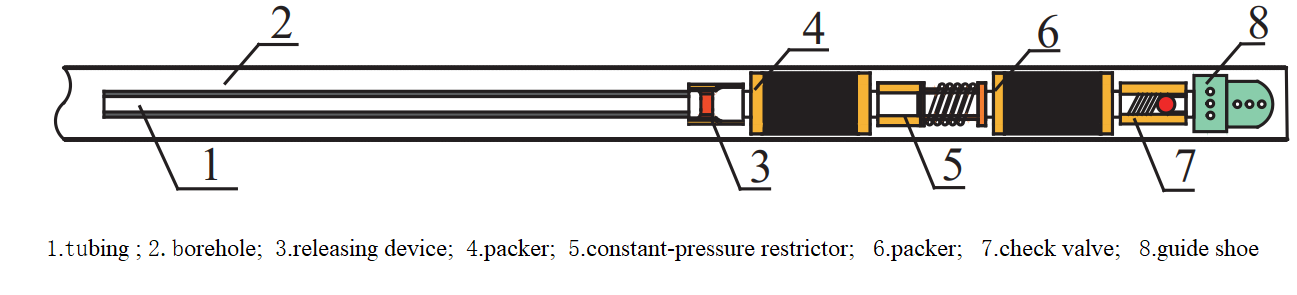

The main function of the staged fracturing tools is to divide the borehole into different fracturing sections and perform staged fracturing and reconstruction on the coal and rock strata. The open-hole staged fracturing tool string is mainly composed of components such as a guide shoe, a check valve, a packer, a constant-pressure restrictor, a releasing device, and tubing. The overall pressure resistance of the staged fracturing tool string reaches over 70 MPa, meeting the requirements for fracturing boreholes with diameters ranging from 89 to 133 mm.

Schematic Diagram of the Combination of Open-Hole Staged Hydaulic Fracturing Tools in Underground Coal Seams